Setting modular units in place requires precise lifting operations, strict control of exclusion zones, and accurate sign-offs of lifting plans.

Modules often need final connections on upper levels, exposing workers to falls without the right safety procedures.

Cranes, telehandlers, and mobile plant operate continuously during module installation, creating high interaction risks.

Modules need M&E tie-ins, often requiring multiple trades working simultaneously in confined areas.

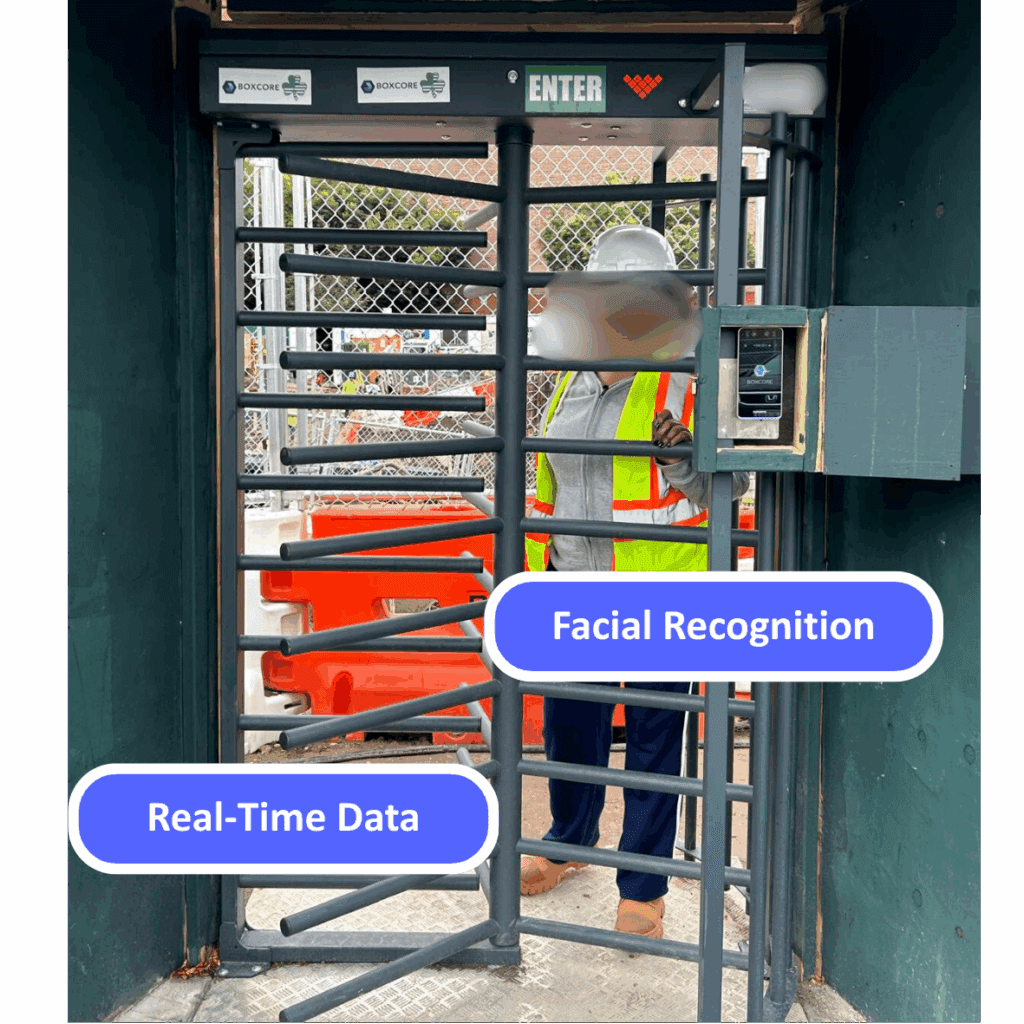

As modules arrive in batches, teams can change quickly, requiring rapid onboarding and training verification.

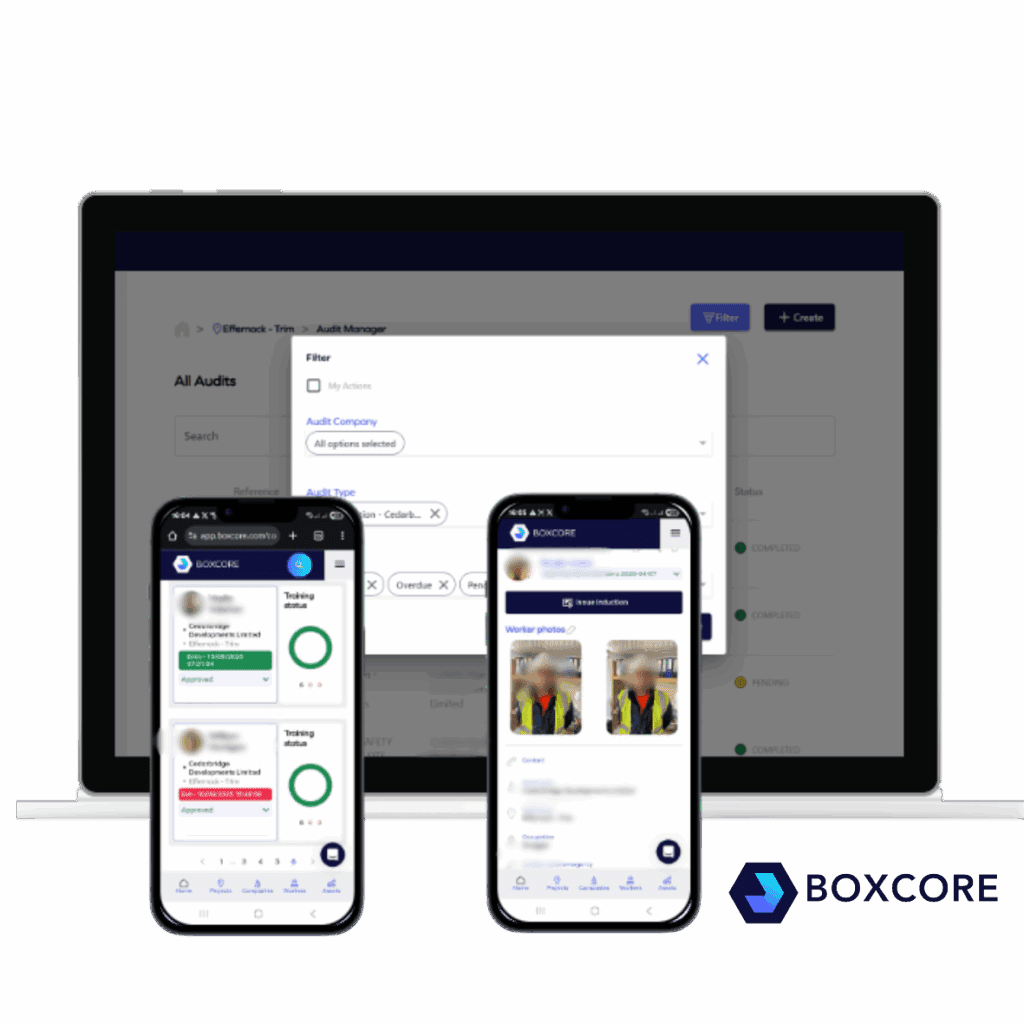

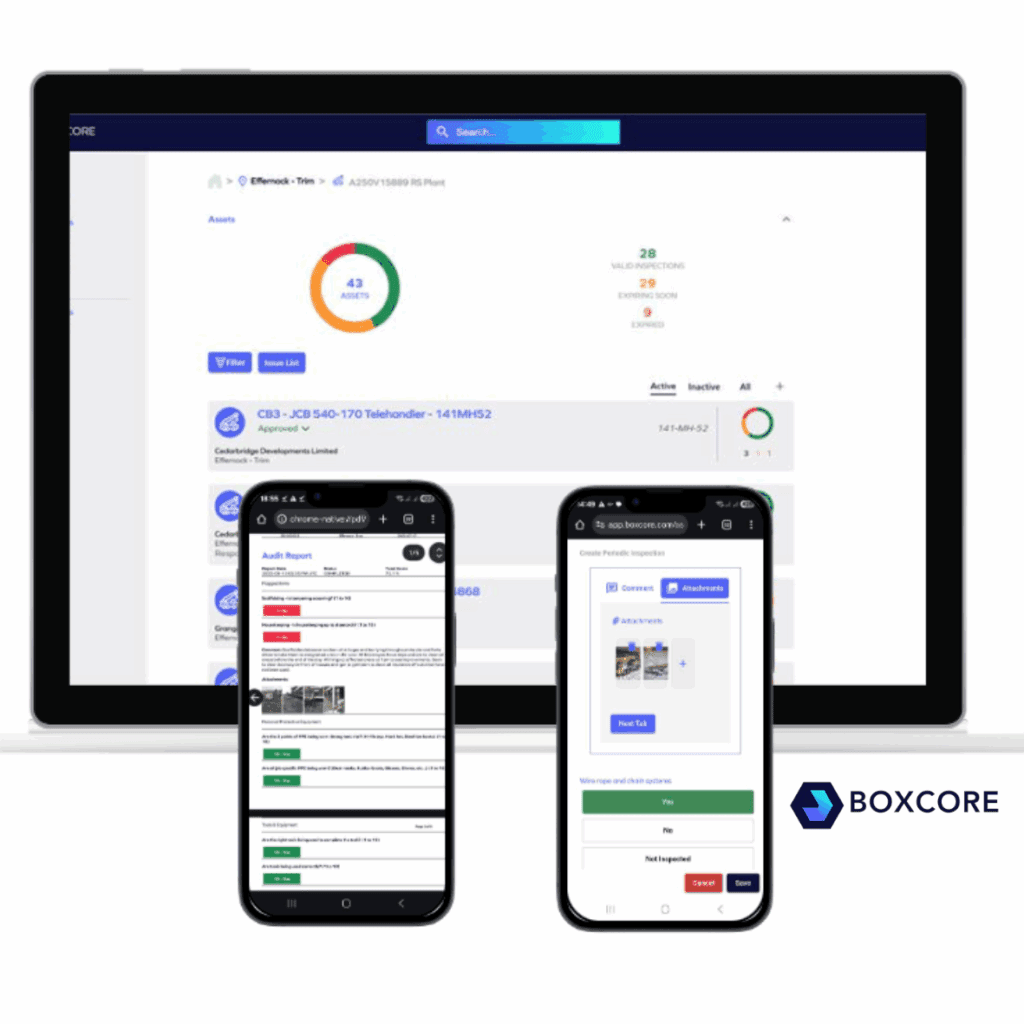

Before any operative sets foot onsite, Boxcore ensures they are Inducted and have the right training and documentation in place. Whether it’s CSCS cards in the UK, SafePass cards in Ireland, or OSHA cards in the USA, everything is stored digitally and visible in seconds. Project-specific inductions, task-specific training, and toolbox talks can also be logged to prove competency across all trades.

From head office to site, Boxcore provides a single source of truth. Managers can see in seconds which crews are onsite, whether training is in date, and if equipment inspections are current. This real-time visibility makes audit preparation straightforward helps keeps projects compliant and removes admin burden from your site teams.