LOLER inspection software is fast becoming essential for UK contractors looking to manage lifting operations with efficiency, safety, and full compliance. From tower cranes to cherry pickers, ensuring that lifting equipment is inspected, tracked, and properly documented is no longer just about ticking boxes—it’s about protecting your workforce, avoiding legal risks, and minimising project downtime.

Paper-based methods and spreadsheets are no longer fit for purpose. They expose contractors to unnecessary risk, delays, and duplicated effort. In contrast, a good digital system not only saves time but directly reduces compliance gaps and boosts site productivity.

In this article, we’ll break down six key things to consider when selecting LOLER inspection software, followed by five concrete benefits you can expect by going digital with a tool like Boxcore.

Six Things to Consider When Choosing LOLER Inspection Software

1. Ease of Use and Speed of Setup

One of the most common reasons digital systems fail in construction is poor frontline adoption. If your site teams find it clunky or hard to navigate, it won’t be used—and your compliance will suffer.

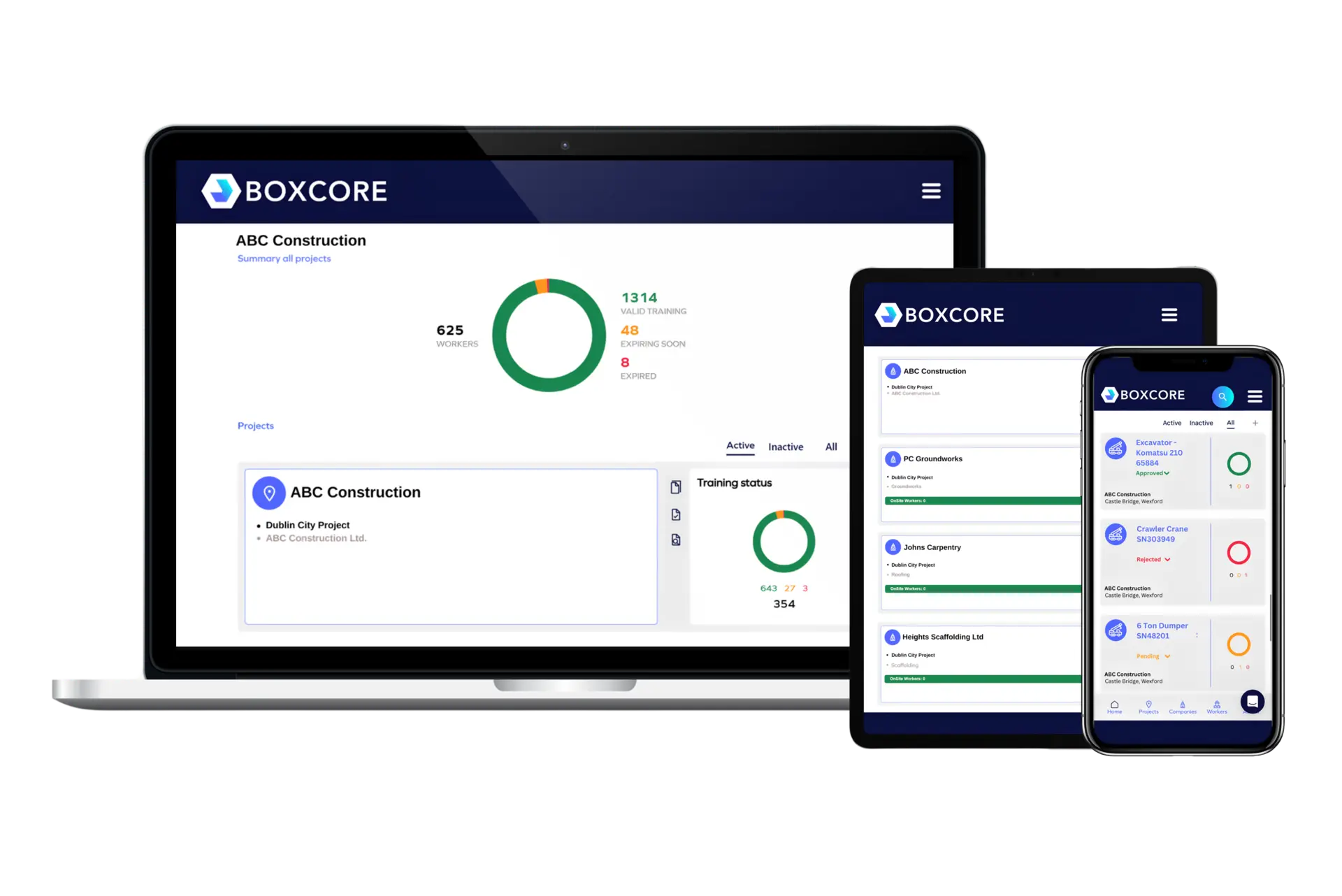

Boxcore is built around the needs of real-world construction teams. Foremen and subcontractors can use the system with minimal training, and full setup is typically completed in less than 48 hours with live data. This is critical for keeping your project timelines on track from day one.

“Software that isn’t immediately easy to use simply won’t get adopted—especially by site crews.” — Padraig Reilly, CEO & Founder of Boxcore

Explore Boxcore’s full feature set here.

2. Automated Reports and Alerts on Issues Raised

LOLER inspections must be conducted at strict intervals – typically every 6 to 12 months depending on the equipment type and usage for thorough inspections and typically weekly for standard inspections. Missing a due date can result in non-compliance and potential enforcement action.

Good LOLER inspection software should include:

- Automatic reminders before inspections are due

- Real-time alerts for failed inspections

- Instant access to issue history and corrective actions

Boxcore automates all of this. You can schedule inspections, assign responsible staff, and track follow-ups- without relying on spreadsheets or chasing people via email.

See how Boxcore streamlines GA2/GA3 inspections.

3. Ability to Easily Share Data with Other Parties

Most contractors don’t operate in isolation. Whether you’re working under a main contractor, joint venture, or sharing equipment across multiple sites, the ability to quickly share LOLER data is crucial.

Boxcore enables instant sharing of inspection records, asset documentation, and maintenance logs via mobile or desktop. No more exporting PDFs, emailing attachments, or maintaining multiple versions of the same file.

This helps ensure all project partners are on the same page—and significantly cuts admin time across the board.

4. System Must Tie in With Other Safety Data

LOLER inspections don’t happen in a vacuum. The right software should connect with related safety data, including:

- Worker training records (CSCS cards)

- Puwer Inspections capability

- RAMS and method statements

- Time and attendance logs

- Site Inductions

Boxcore was designed with this exact integration in mind. It provides a single source of truth across all safety workflows. For example, only trained operatives can be assigned to operate specific lifting equipment, ensuring your RAMS and LOLER compliance align.

This integrated approach is covered in Boxcore’s Loler Inspection software

5. Ability to Assign Inspection Location Easily

Being able to track equipment across multiple sites is vital. Whether you’re managing a single large development or several smaller jobs, you need to know where each piece of lifting equipment is, its inspection status, and which team is responsible.

Boxcore’s Loler inspection software lets you assign each asset to a specific location or project. As soon as a crane or hoist moves to another site, the record follows it – ensuring full traceability.

This is especially useful for subcontractors who move between sites regularly and need to prove compliance at each handover point. Learn more about Boxcore’s subcontractor tools.

6. Built for the Realities of UK Construction

Many LOLER Inspection software platforms are either too generic or built for office use, not site teams. Boxcore is different. Built by civil engineers and project managers, it’s tailored for the boots-on-the-ground realities of UK construction sites.

From integration with CSCS cards to automated asset registers and secure mobile access, the entire system is designed to help UK contractors meet their legal obligations under LOLER, PUWER, and broader CDM regulations – without overwhelming admin staff or safety officers.

For more on Boxcore’s UK-specific solutions, see Golden Thread: A Burden or Opportunity?

Five Key Benefits of Going Digital with LOLER Inspection Software

1. Reduced Compliance Risk

Manual systems are error-prone. Files go missing, dates are missed, and responsibilities fall through the cracks. Digital LOLER inspection software ensures everything is tracked, timestamped, and easily retrievable for audits or enforcement visits.

By having a structured, traceable system, you significantly reduce the chance of falling foul of HSE inspections or CDM breaches—particularly on larger or high-risk projects.

2. Eliminate Over 90% of Manual Admin

Many contractors still rely on paper forms or Excel registers that need to be updated manually. These methods eat up hours every week for safety managers and site admins.

Boxcore cuts that admin by more than 90%—not just for LOLER inspections, but across all safety data management. From automated registers to pre-filled digital inspection forms, teams can get back to building, not form-filling.

For more insights, see how Boxcore helps eliminate spreadsheets in construction safety.

3. Reduced Insurance Costs

Demonstrating a robust digital safety record can often support lower insurance premiums or improve your standing when bidding for work.

By using software that keeps your LOLER records up to date, tied to operator training and accessible at all times, you can provide your insurer or client with clear evidence of risk management.

More importantly, in the event of an incident, having full digital traceability could protect your company from costly claims or delays. The right Loler Inspection software ensures you are not exposed to liability and residual risk

4. Improved Productivity on Site

Missed inspections or delays due to inaccessible equipment can bring whole sections of a site to a standstill.

Boxcore’s Loler inspection software helps avoid this by giving real-time visibility of what equipment is in use, what’s certified, and what actions are pending. No more “waiting around for a sign-off” or sending someone to chase down a document.

In fact, this operational clarity has helped clients see productivity improvements across hundreds of live projects.

5. Supports Growth and Scalability

As your projects or subcontracting work grows, so too does the complexity of your compliance obligations. Boxcore’s LOLER Inspection software solution is scalable from a single site to dozens, with consistent records, audit readiness, and role-based access controls.

Whether you’re a local SME looking to tidy up your internal process or a Tier One firm managing a high-risk lift zone, the same system scales with you.

This is particularly useful for firms targeting ISO 45001 certification or working in sectors with higher scrutiny such as data centres and infrastructure.

Final Thoughts: LOLER Software That Works on Site, Not Just in the Office

LOLER inspection software should not be an extra burden—it should make your life easier. For UK contractors, the shift from paper to digital is no longer optional. It’s the simplest way to ensure safety, prove compliance, and eliminate the bottlenecks that slow down your build.

Boxcore’s strength lies in its simplicity. It’s built for frontline users, not just office-based safety managers. Whether you’re running a two-week lift plan or managing a rotating fleet of lifting gear, the system ensures every piece of equipment has a clear, auditable safety trail.

“At the end of the day, our goal is simple: we want to give contractors tools that actually make their lives easier on site.” — Padraig Reilly, CEO & Founder of Boxcore

If you’re ready to reduce admin, lower your compliance risk, and make safety audits easier, it’s time to consider a system built specifically for your site teams.

Learn more about how Boxcore’s Loler inspection software can support your lifting operations and overall site safety: book a demo today and see when over 200 Contractors of all sizes are using Boxcore to make their teams safer and more productive.